Industrial heat

transfer experts

The local expert you can rely on

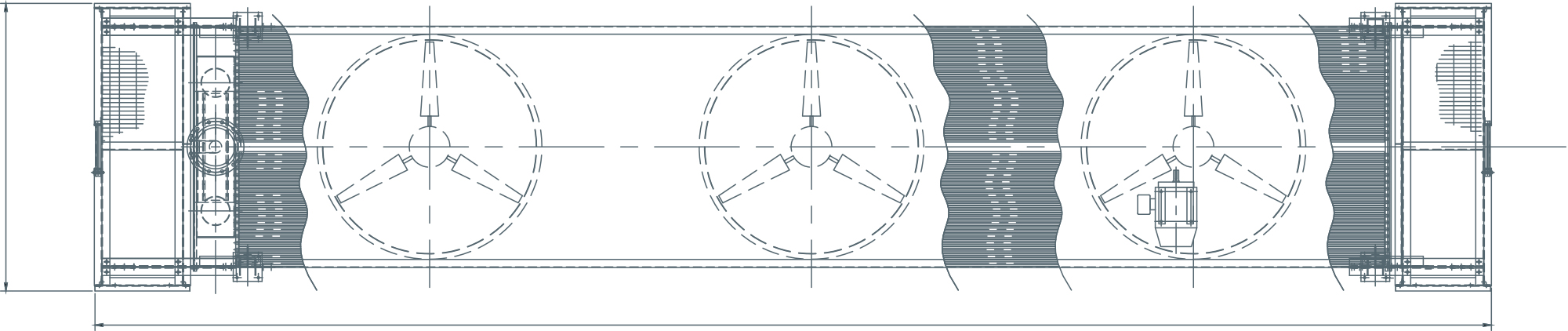

Extran is committed to providing our clients with the most effective heat transfer design solutions and to remain a quality, competitive provider in terms of supply, manufacture, maintenance, cleaning, site service and spare parts supply.

Our in-house expertise enables us to address technically sophisticated projects and, through our partnerships with global leaders, more technically sophisticated equipment supply.

Our Maintenance Workshop has an enviable reputation for the service, rebuild and repair of Heat Exchangers, Oil Coolers, Air Coolers, Plate Heat Exchangers, Shell and Tube Heat Exchangers and Industrial Radiators.

We have the engineering depth for complex heat transfer solutions in both Thermal and Mechanical Design disciplines and code conformance requirements with design capabilities that include AS 1210, AS4041, ASME (Div 1 & 2), PD 5500, API661 and TEMA.

Good design is all about expertise + teamwork

In-house Engineering

Whatever you have in mind, our in-house engineering department can work with you to develop bespoke, advanced heat transfer solutions that are just right for your unique industry and application.

Responsible innovation is good for business and the environment